Microbial Barrier Testing is primarily performed on materials used in the construction of a sterile barrier system. This testing helps characterize a material’s microbial barrier properties. This testing differs from integrity testing as it tests the material’s inherent ability to prevent microbial ingress. The method utilized depends on the permeability of the material. The most commonly used tests include the following:

- ASTM F1608 Microbial Ranking of Porous Packaging Materials (Exposure Chamber Method)

- ASTM F2981 Standard Test Method for Verifying Nonporous Flexible Barrier Material Resistance to the Passage of Air

- ASTM F1608 is utilized when evaluating porous materials and ASTM F2981 for nonporous materials. When neither test method are compatible with the SBS, alternative methods may be selected. Contact us if you need help determining which test may be most appropriate.

Applicable Standards

- ISO 11607

- AAMI TIR17

Test Overview

F1608

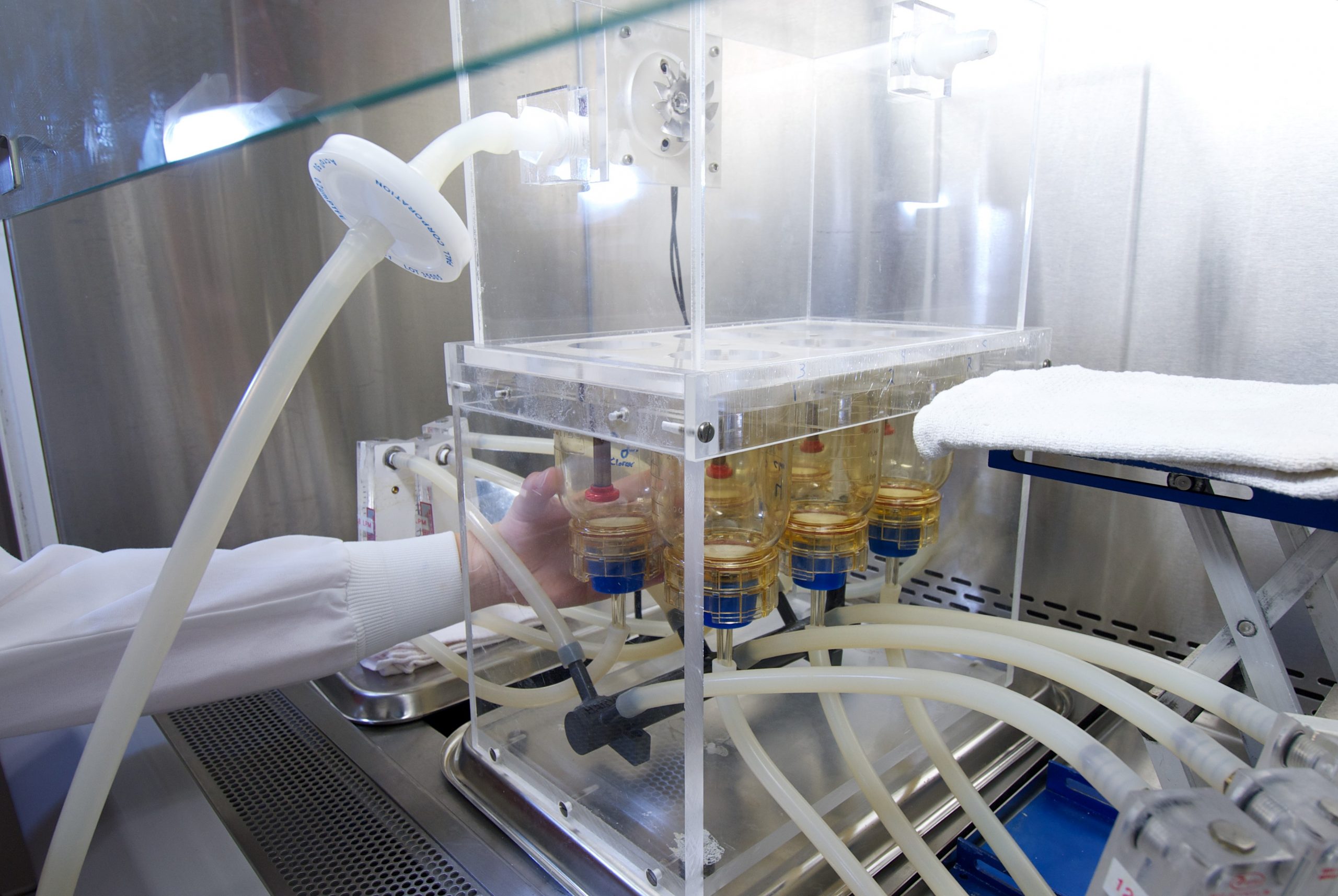

Testing is performed per ASTM F1608 to evaluate the microbial barrier performance of porous packaging materials, such as medical paper and Tyvek®. A portion of the packaging material is placed overtop a filter, exposed to aerosolized Bacillus atrophaeus spores, and a vacuum is applied. Spores are drawn through the packaging material and collected on the filter underneath. Spores are then extracted from the filter and enumerated. The number of organisms from the filter are compared against a non-blocked filter to calculate a log reduction value. Higher log reduction values indicate better microbial barrier performance.

Gurley Non-Porous Verification

Gurley testing is performed per ASTM 2981 and evaluates a material’s impermeability. Impermeable, or nonporous materials, are considered adequate microbial barriers. The material is secured in a Gurley Densometer that attempts to pass air through the material. The starting position of the apparatus’s inner cylinder is recorded, then measured again one hour later to determine if a >1 mm change in position has occurred. If the position has not changed >1 mm between the two measurements, the material is verified as nonporous.

Aerosol Fallout

The Microbial Aerosol Fallout Challenge test method can satisfy the requirement for porous materials, as outlined in ISO 11607 for microbial barrier testing when other consensus standards are not appropriate. This test is not intended to detect artificially created defects to establish sensitivity detection levels in packaging materials. In cases where artificially created defects and sensitivity are required, established integrity tests would be more appropriate.