Cleaning Validation Testing for Reusable Devices

Nelson Labs offers a full range of cleaning validation services to validate manufacturers’ cleaning instructions for reusable medical devices. This includes soiling, cleaning, and post-cleaning effectiveness testing (i.e., analytical or microbial methods). Simulated-use testing practices are employed to assess worst-case clinical use of the medical device during the validation. Our experts can help to determine the appropriate test methods, clinically relevant test soils, and interpretation of the data collected. This testing complies with AAMI TIR12, AAMI ST98, ISO 17664 series, ISO 15883 series, and the FDA guidance document “Reprocessing Medical Devices in Health Care Settings: Validation Methods and Labeling.” The experts at Nelson Labs actively serve on applicable AAMI, ISO, and ASTM committees and have expertise in creating appropriate worst-case testing conditions to help device manufacturers meet regulatory expectations. View our Reusable Device Cleaning Recommendations.

Applicable Standards

- AAMI TIR12

- AAMI ST98

- ISO 17664 series

- ISO 15883 series

- ASTM F3208

- ASTM F3321

- FDA guidance documents

Device Type Expertise*

- Surgical Instruments

- Orthopedics

- ENT

- Dental

- Respiratory

- Flexible/Rigid Endoscopes and accessories

- Robotics

- Dialysis

- Homecare

- Extractions for Single Use Reprocessors

- Capital Equipment

* Our scope of expertise is continuously expanding. A Nelson Labs expert can help develop methods and test plans for a variety of devices outside of the specifics listed above.

Study Outline

Cleaning validations evaluate the manufacturers’ recommended cleaning procedure for a reusable device. This validation is necessary to ensure that once the device has been used, it can be properly cleaned prior to disinfection or sterilization and reuse. It is the responsibility of the manufacturer to apply these data, along with functionality, end-of-life, and disinfection/sterilization data, to the instructions for use. Nelson Labs experts are available to help manufacturers develop a cleaning procedure to be validated for their instructions for use.

Soiling: The devices are soiled using an appropriate test soil with clinically relevant markers such as protein, hemoglobin, total organic carbon, and carbohydrates. Nelson Labs experts can help to determine the appropriate test soils and soiling method by considering the device’s intended use and worst-case wait time between uses.

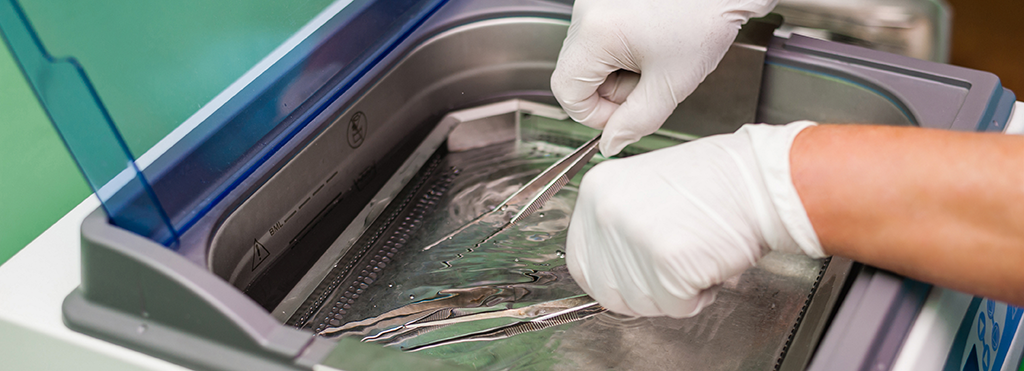

Cleaning: The devices will be cleaned using the worst-case cleaning procedures based on the manufacturers’ instructions for use. Cleaning procedures may include manual, automated (i.e. washer/disinfector or automated endoscope reprocessor), and/or mechanical processes (i.e. sonication). Nelson Labs can also accommodate any custom processes for validation.

Post-cleaning effectiveness testing: After the devices are cleaned, they are extracted using a validated method to assess the effectiveness of the cleaning procedure. The extraction fluid is then evaluated to determine the presence of residual soil components remaining on the device. This testing, combined with visual inspection, helps to validate the effectiveness of the cleaning procedure.

Testing Locations

- Salt Lake City, UT, USA

- Leuven, Belgium

Learn more about our locations and their certifications.

Contact Us

If you have additional questions about Cleaning Validation services for reusable devices, or would like to consult with the experts at Nelson Labs, just send us a request or call us at +1 (801) 290-7500.