Overview

National Institute of Safety and Health (NIOSH) evaluates and approves all respirators intended for use in healthcare and other workplace settings within the United States. As a part of the assessment process, NIOSH conducts comprehensive in-house testing. However, prior to application submission, preliminary testing (or “pre-submission testing”) must first be completed by the manufacturer or a third-party laboratory to verify that minimum performance requirements are met.

Pre-submission testing must follow strict guidelines as outlined in the Code of Federal Regulations (CFR). To avoid application delays or rejections, manufacturers should ensure that all appropriate pre-submission testing is completed with adequate documentation and that only high-quality testing is conducted.

Required testing may include Sodium Chloride, Dioctyl Phthalate, inhalation/exhalation, and valve leak tests to assess filtration, breathability, and leakage. For surgical N95s, which are concurrently regulated by the FDA as class II medical devices, additional pre-submission testing includes flammability, fluid resistance, and biocompatibility.

Applicable Standards

- NIOSH 95

- 42 CFR Part 84

- NIOSH Procedure No. TEB-APR-STP-0057-0058-0059

Download our respirator testing requirements PDF to assist you in determining which tests are required for the U.S. market.

Types of NIOSH-Certified Respirators

Pre-submission testing requirements vary by respirator type. NIOSH categorizes filters based on the resistance to filter efficiency degradation (i.e., oil resistance) of the filtering media and the particle filtration efficiency. There are three categories for NIOSH-certified, nonpowered, air-purifying, particulate-filter respirators:

| Type | Details |

| N | Not resistant to oil N95, N99, and N100 filter at least 95%, 99%, and 99.97% of airborne particles |

| R | Somewhat resistant to oil R95, R99, and R100 filter at least 95%, 99%, and 99.97% of airborne particles |

| P | Strongly resistant to oil (oil proof) P95, P99, and P100 filter at least 95%, 99%, and 99.97% of airborne particles |

N-Series masks are appropriate for use in the absence of oil particles (e.g., lubricants, cutting fluids, glycerin, etc.). In the presence of oil particles, R- or P-series filters should be used. If a filter will be used for multiple shifts when oil is present, P-series filters are most appropriate for use.

Pre-Submission Testing Requirements

All testing must comply with NIOSH Standard Testing Procedures (STPs) and use appropriate instrumentation as outlined in 42 CFR Park 84 and NIOSH Procedures TEB-ABR-STP-0003, 0004, 0007, and 00051-59. Nelson Labs has extensive experience in this testing as well as other testing for filters and filtration devices.

| Category | Filter Class | Particle Filtration Efficiency Test | Breathability Test | Valve Leak Test | ||

| N, R, or P | 95, 99, or 100 | Test Agent | Efficiency | Inhalation | Exhalation | If Applicable |

| N-Series | N95 N99 N100 | NaCl | ≥95% ≥99% ≥99.7% | ≤35mm | ≤25mm | ≤30mL/min |

| R-Series | R95 R99 R100 | DOP | ≥95% ≥99% ≥99.7% | ≤35mm | ≤25mm | ≤30mL/min |

| P-Series | P95 P99 P100 | DOP | ≥95% ≥99% ≥99.7% | ≤35mm | ≤25mm | ≤30mL/min |

Testing Locations

- Salt Lake City, UT, USA

Learn more about our locations and their certifications.

Study Outline

Particle Filtration Efficiency Testing

Sample Size = 20 respirators

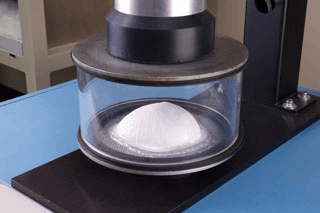

Filtration efficiency testing is conducted to determine the percentage of particles filtered by the respirator, using either Sodium Chloride (NaCl) or Dioctyl Phthalate (DOP) as the test agent. Sodium chloride is considered only slightly degrading to filter efficiency and is used to test N-series respirators. Dioctyl Phthalate (DOP) is considered very degrading and is used to test R-Series and P-series respirators.

- The Sodium Chloride Aerosol Test (NaCl) – NRC110

In this test, respirators are conditioned at 85% Relative Humidity (RH) and 38°C for 25 hours. After conditioning, filters are put into a test system that passes a neutralized NaCl aerosol through the sample at a rate of 85 L/min. Masks are loaded with NaCl until either the maximum penetration level is reached or the filter exceeds the designated particle limit of 200mg.The concentration of NaCl is then measured before and after impact with the filter. The amount of NaCl that passes through is used to calculate the filtration efficiency of the sample. The maximum filter penetration that can occur to maintain an N95 rating is less than or equal to 5% (≥95% efficiency). Similarly, for an N99 rating the maximum filter penetration is ≤1% (≥99% efficiency).

- The Dioctyl Phthalate (DOP) Oil Test – NRC115

In this test, samples are instead subjected to DOP oil. The maximum filter penetration that can occur to maintain an R95 or P95 rating is less than or equal to 5% (≥95 % efficiency). For an R99 or P99 rating, the maximum filter penetration is ≤1% (≥99 % efficiency).

Breathability Testing – NRC120

Sample Size = 3 respirators

To determine breathability, two tests—exhalation and inhalation resistance—are performed to mimic airflow resistance while breathing in and out. Low levels of exhalation and inhalation resistance represent ease of breathing for the user.

In this test, a 6-inch slant water manometer (U-shaped tube containing liquid) is used to measure the differential pressure on either side of the filter. This pressure difference is taken both upstream and downstream to determine the directions of exhalation and inhalation, per 42 CFR Part 84.180, with results measured in mm of H2O. To comply with minimum NIOSH breathability requirements, initial Inhalation resistance cannot exceed 35 mm of H2O and initial exhalation resistance cannot exceed 25 mm of H2O.

Value Leak Testing – NRC125

Sample Size = 3 respirators

Valve leakage testing is only necessary if the product contains an exhalation valve, which allows air to flow out of the respirator during exhalation and prevents inward flow during inhalation. Respirators with exhalation valves protect the user from the outside environment only.

For this test, the bubble meter method is used to determine the gas flow rate. Three valves are removed from respirators and inserted into a digital soap film flowmeter, which calculates the time taken for the soap bubble to travel from one set mark to another within the known tube volume. To meet NIOSH minimum requirements, leakage cannot exceed 30 mL/min.