While attending the annual Society of Toxicology meeting, I sat in on the Innovations in Toxicological Science symposium’s In Vitro Systems: Advancing Regulatory Science Through Innovation presentation. During this session the presenter discussed new in vitro methods that have been developed to test the safety and efficacy of new drugs and medical devices on human beings.

The cost of developing new drugs and medical devices is huge. The trends to better manage these costs involve making in vitro alternatives for making small-body systems to mimic what we would do with an organ or full body, sometimes called pseudo-humans.

With pseudo-humans, we can study a device or a drug to see how safe it would be before we take it to clinical trials, or test it on animals. This kind of system is faster at determining the safety and efficacy of pharmaceuticals and medical devices.

In addition, it can take years and millions of dollars to conduct tests on animals, but we know animals and humans aren’t directly correlated. So if we can come up with a system that is more predictive of safety, and is quicker and cheaper, we can move faster and be more confident of safety before moving onto clinical trials.

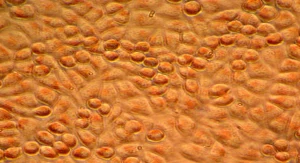

Pseudo-human tests are still in development, but a springboard test we already use at Nelson Laboratories is an in-vitro irritation test using dermal cells. Using stem cells, we grow a dermis to which we apply liquid that a medical device has soaked in. After application, we look for signs of irritation as a result of contact with the device.

We are currently working to get this in vitro irritation test to be a standard method for medical devices, so we no longer need to rely on animal testing. While this is not the same as using pseudo-humans for testing, it is a new form of testing already yielding positive results for Nelson Laboratories and our clients.

It has also become increasingly useful to utilize consultants when conducting tests. Their expertise aids in preventing unnecessary testing, which in the long run is less expensive and more productive for our clients.

Previously, we just performed the tests. Now, we are also focused on conducting safety assessments. We work with someone to determine the potential toxicity that would impact the patient, and consult with a toxicologist to determine what testing to do and examine the results. This prevents unnecessary testing and saves time and money in the long run.

We are currently working with a company with a device made of stainless steel. Together with a consultant, we looked at the process of making the device as well as the chemicals coming off of the device. By identifying these chemicals, we addressed the safety of the individual chemicals and determined which tests were needed and which were unnecessary. We conducted about two weeks of testing and research and eliminated the need for animal testing. This not only saved time, but was also done at a fraction of the normal cost.

While many technologies are years away from being used on a regular basis, significant advances are taking place now.